Pressure cooking is a wonderful way to prepare food that cooks thoroughly and quickly at a high temperature. Some are worried about the dangers of using a pressure cooker, so it is helpful to find out how to check your pressure cooker safety valve for safe operation.

In this article you will learn:

- What is a pressure cooker safety valve?

- How does the valve work?

- What does the steam coming out mean?

- What causes a cooker to stop working properly?

- What do you do if the valve needs repair?

Contents

- 1. What Is a Pressure Cooker Safety Valve? →

- 2. What a Pressure Cooker Safety Valve Does →

- 3. Pressure Cooker Steam Coming Out of Safety Valve →

- 4. Pressure Cooker Valve Not Working →

- 5. Pressure Cooker Valve Repair →

- 6. Pressure Cooker Valve Replacement →

- 7. Are Pressure Cookers Safe? →

- 8. Useful Resources →

What Is a Pressure Cooker Safety Valve?

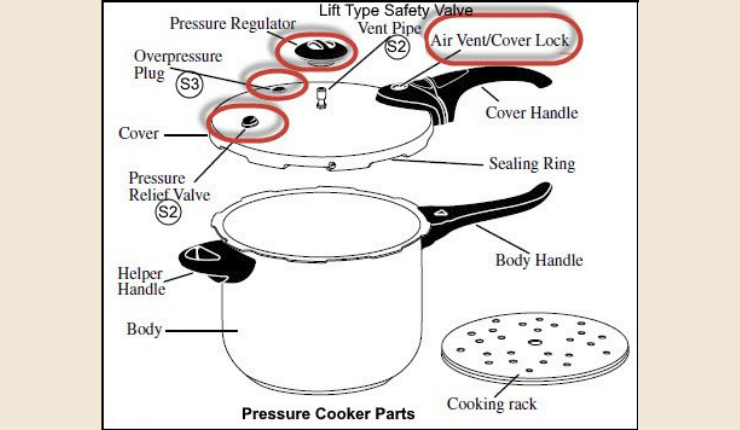

The safety valve on a pressure cooker is a feature that will release steam if the internal pressure rises above a certain level.

For those worried that a pressure cooker might explode, the safety valve is the design feature that prevents this from happening. If the cooker has a safety valve, you can see it installed on the cooker’s lid.

A pressure cooker is designed to trap the steam inside to increase the pressure. However, too much pressure is not safe. The valve must release pressure if it gets too high.

It is harder to bring water to a boil in areas with a high altitude, so a pressure cooker is very useful for making pasta in those areas.

The blog of pressure cooking today has many recipes that are delicious. There are 25 recipes for pasta so you can try a new one every day for nearly a month.

What a Pressure Cooker Safety Valve Does

There is a weight inside many of the safety valves that is lifted by the internal steam pressure when it reaches a certain amount. When the pressure lifts the weight inside the valve, this allows some steam to escape.

Jeffrey Eisner who says “he is a nice Jewish boy from Long Island.” He started with pressure cooking by making a simple mac and cheese dish with a recipe that he shared on YouTube. The video was an immediate success and led to his making new recipes for pressure cooking.

In a sealed cooker, as the pressure builds up, the boiling point of water rises. This phenomenon is the cause of the increased heat that cooks the food more thoroughly and faster.

The science that explains this is fascinating. The normal boiling point of water under standard atmospheric pressure of 15 pounds per square inch (psi) is 212°F (100°C). In a pressure cooker, the atmospheric pressure doubles from 15 psi to 30 psi. This added pressure raises the boiling point of water from 212°F (100°C) to 250°F (121°C).

In this video from America’s Test Kitchen, the narrator explains the science behind pressure cookers.

Higher pressure means that the water can heat up more until it boils.

Pressure Cooker Steam Coming Out of Safety Valve

If you see steam escaping from the safely valve do not worry. The steam escaping from the safety valve is its normal function, which means the valve is working properly.

If the internal pressure within the cooker gets high enough, this lifts a weight in the safety valve that allows steam to escape. The escaping vapor lowers the pressure. You can hear the steam escaping, making a whistling sound, or rattling the valve.

The first pressure cooking devices were used in the 17th century. They were useful to remove fat and collagen from bones so that the bones could then be ground down to make a pure bone meal.

The inventor of the device, Denis Papin, called it a “steam digester” or “bone digester.” His invention was the precursor to both pressure cookers and the steam engine. Surprisingly, the early designs did not have any safety features, and this caused some of the first ones to explode while being used.

The steam you see coming out the top of the pressure cooker is actually the soul of the cow escaping #masterchefau

— Ben Pobjie (@HartWexford) May 16, 2021

The legacy of those early pressure-cooking devices may be why some still fear this problem even today. Papin, to his credit, came up with a design improvement that is what we call a safety valve to avoid the dangers of these explosions.

By the 1930s, the modern pressure cooker design became useful in a home kitchen. The Flex-Seal Speed Cooker, invented by Alfred Vischer, came out in 1938.

These home cookers became even more popular in 1939 with the release of the design by the National Pressure Cooker Company (now called National Presto Industries), which is still manufacturing these cookers today.

The first-generation cookers had a safety valve that worked with a weight. When the internal pressure rises high enough to lift the weight, some steam escapes, and the valve makes a distinctive rattling sound.

Cut the heat down and removed the lid

This pot is a vintage 1950’s pressure cooker

Snag one at a flea market if you can. It does everything pic.twitter.com/BlxYr2jCFp— PaganChild (@PaganChild) December 13, 2020

Second-generation cookers use a spring-loaded valve that makes less noise and is adjustable for pressure sensitivity by using a dial, which is on the cooker.

Third-generation models are the most recent versions. They use an electric heating source that is regulated by the internal pressure. These devices do not need a safety valve because the heat source automatically shuts off before the pressure gets too high.

Suppose you are thinking about getting a new cooker. In that case, there is another device that you might consider called a food dehydrator, which I describe in the article entitled, “How Much Electricity Does a Dehydrator Use?” here.

Pressure Cooker Valve Not Working

For the styles of cookers with a safety valve, it may not be obvious when the valve is not working if it is blocked. You may notice the lack of steam while the cooker is heated. The valve could rarely be blocked, but if not cleaned properly, it is possible.

Alternatively, the valve may be broken, missing, or the pot may not seal properly. These problems might allow too much steam to escape. This leakage may cause the cooker not to heat up properly and not allow the internal pressure to build up to the proper level.

One of the signs of a problem with a lack of pressure is that the food takes much longer to cook than you normally expect when using a cooker of this type.

In this video by Tom Mater, you can see how to replace a valve on a pressure cooker and do basic maintenance to keep it working properly.

One tip in the video is not to open the cooker after finishing cooking and take the lid to run it under cold water. This sudden temperature change can make the safety valve work less well and may cause the need to change the valve more frequently.

Learn some more kitchen safety tips in my article about what to do if an air fryer sets off the smoke alarm here.

Pressure Cooker Valve Repair

If you use a cooker that needs a valve to work properly and the valve is broken or missing, you can replace it with a new valve. Be sure to get the manufacturer’s specifications to ensure you use the correct replacement part.

There may be other problems that keep your cooker from pressurizing properly, which are discussed in this video by Six Sisters’ Stuff.

Some of these problems include the ventilation knob being open or not enough liquid is in the cooker (requires at least one cup). Another cause is the sealing ring is missing, damaged, covered with food particles, or not in the proper position.

The video narrator shows how she cleans her float valve for her instant pot that she uses as a cooker. If you use too little liquid or too much, the cooker may not pressurize.

Pressure Cooker Valve Replacement

It is quite easy to replace a pressure cooker valve if you have the correct replacement part.

For most of these valves, all you need is a screwdriver and some pliers, perhaps a wrench and socket if it is the kind that does not use screws.

For the type with screws, hold the valve from the bottom of the lid with the pliers and use the screwdriver to remove the screws from the top to remove the broken part. Replace it with the new one and tighten the screws that hold it in place by holding it with the pliers from the bottom of the lid again and tightening the screws from the top.

For the type with a nut, use the wrench to loosen it for removal and perhaps a socket when you put on the new valve to tighten it with enough torque to hold it securely in the proper position.

This video by Science Sir shows how to replace Hawkins pressure cooker safety valve.

As you can see in the video, replacing a safety valve is pretty easy to do.

Are Pressure Cookers Safe?

Modern pressure cookers that are in good repair are quite safe. The one caution to remember is not to overfill the cooker so that the food might block the safety valve. This overfilling with food would be very difficult to do and not something to worry about for normal use.

Be careful where you keep your cooker on the countertop because it is important to know how hot a stovetop can get. Even when turned off, a stovetop may still be very hot, which I discuss in this article.

Useful Resources

- How to use a pressure cooker →

- 50 easy instant pot recipes →

- Instant pot chicken breasts (fresh or frozen) →

Finishing Up

Now you know everything you need to know about a pressure cooker safety valve. You know what they do, how they work, and how to replace one if it needs repair. Enjoy your pressure-cooking recipes without worrying about the safety valve.

If having a safety valve on your cooker still bothers you, consider buying an electric cooker without a valve that instead has a built-in safety feature that automatically shuts off power if the pressure gets too high.

- Lava Rocks Vs. Fire Glass – What Is Better for a Fire Pit? - November 15, 2023

- How to Light a Propane/Gas Fire Pit with a Manual or Electronic Ignition System - November 8, 2023

- How Long Does a Propane Tank Last for a Fire Pit - October 9, 2023